My Eddy current brake is a official one from the firm Siemens

Although it weight quit heavy, the brake power is limited. The frond panel tells a Max of 1,3KW (about 1,7HP)

The idea for this component is to simulate a road, so it does not need to brake hard just a little bit so I can check the fueling.

Its a siemens 2GA3375-1B

- 1500MIN-1/1.1 KW

- 3000MIN-1/1.3 KW

- 0 TO 180V DC/ 2.5A

With pulse sensor for RPM

With a small loadcel

24mm shaft

Size comparison

Eddy current brake vs. Powder clutch brake

Update: 28-10-2018

One problem to solve is the difference in shaft diameter

The eddy current has a 24mm and the dyno has a 40mm

My adapter flange plate has 30mm, so needed to make a adapter from 24 to 30mm

Here we go

Starting with a lump piece off steel

Starting on the center hole

Getting close

Final internal diameter 24mm

Ready for cutting a peace out

Fits the shaft.

Fits the flange

All mounted ready to go

Look at that, its a beauty

Update: 01-06-2019

Today was a big day, had my first impression from the eddy current brake in action.

But before I was there I needed to get thinks back together

Frame is looking better ones it is sprayed in hammer right paint (light blue)

Hopefully the last time I lifted the drum

Almost ready to drop in its final resting place

There she sits

Eddy current brake also on its place

Home made connection from 40mm to 24mm with flexible rubber to allow a slightly wrong alignment (tried it as tight as possible)

The starter system, looks great

Had to place the whole construction at the back off my work shop, as it still needs lot off work.

It can stand there until its completely ready

It had to be my trusty NSU Super Lux (low rpm, limited sound) who had the honor to test the eddy current brake setup.

At least to give me a indication how it all holds.

(I could not use my TZR125 as it screams through the whole neighborhood, wont make friend with that)

And here you can here me playing with the current, and my old NSU had to work harder.

Update: 08-06-2019

Today mounted the TZR125 to see how the Eddy current brake is holding with higher RPM and speeds.

Shifted up to sixth gear, around 6000rpm and activated the brake.

It looks like she is holding all right, you can hear that the engine has some load not much but it sounds like road condition.

Need to investigate this further, I'm happy so far

There she is standing

Started to construct a top plate to cover/protect all parts.

Not ready jet, but it starts to look good

Also started on the exhaust suction holder, with Lambda controller

The eddy current brake I use has a internal mass drum where the electric field is going through.

This Drum has a certain mass that needed to be calculated

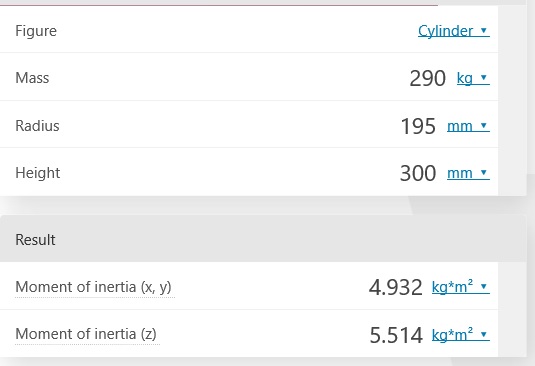

Drum 1 (wheel rol)

D=390mm

h=300mm

metal=7900

shaft 125 x 40 (two times)

V=pi x r2 x h

Drum

V=3,14x(0,195x0,195)x0.300=0,03582x7900=282,978kg

Shaft (coming out off the drum)

V=3.14x(0,020x0,020)x0,125=0,000157x7900=1,2403kg (that two time) =2,4806kg

Starter plate

V=4,55kg

Total weight 2,4806+282,978+4,55=290,0086kg

I = m/2 x r2

I = 290,0086/2 x (0,195x0,195)=5,51

metal=7900

shaft 125 x 40 (two times)

V=pi x r2 x h

Drum

V=3,14x(0,195x0,195)x0.300=0,03582x7900=282,978kg

Shaft (coming out off the drum)

V=3.14x(0,020x0,020)x0,125=0,000157x7900=1,2403kg (that two time) =2,4806kg

Starter plate

V=4,55kg

Total weight 2,4806+282,978+4,55=290,0086kg

I = m/2 x r2

I = 290,0086/2 x (0,195x0,195)=5,51

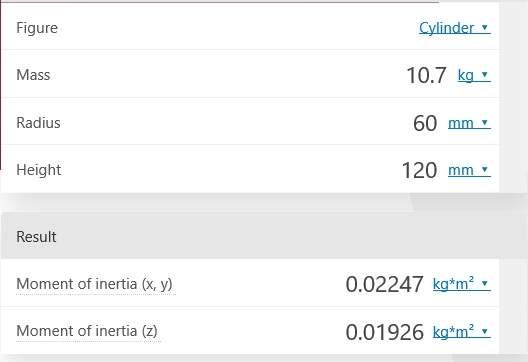

Drum 2 (eddy current brake rol)

D=120mm

h=120mm

V=pi x r2 x h

V= 3.14x(0,060x0,060)x0,120x7900= 10,72Kg

I = m/2 x r2

I = 10,7/2 x (0,060x0,060)=0,01926

I could calculate the two outgoing 20mm shafts but as you can see that will not be necessary

Think when I ad 0,2 inertia to the already calculated inertia it will be OK

So 5,51+0,02=5,53

Total inertia will be 5,53kgm2

Next problem is the cooling, after some small tests it turns out the eddy current brake is getting hot quick.

So need to add a blower to keep it as cool as possible

Starting with a wooden plate

(will be painted off course)

And here you go.

1250 3m air right on the brake